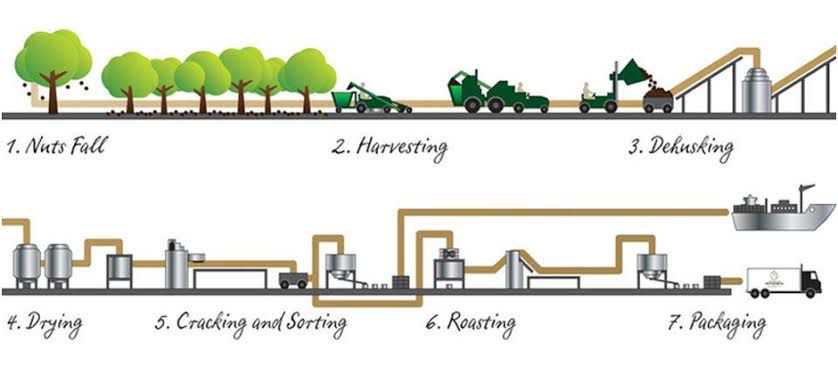

The technology used for preparing macadamia nuts is constantly being improved for speed and efficiency. The major concerns of processors are kernel damage, contamination, product availability, and distribution.

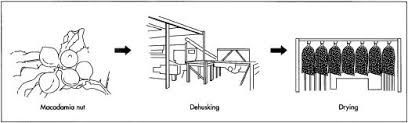

Most macadamia nut processing plants are situated close to growing districts. The nut-in-shell farm produce is delivered to the plant where it is stored in to dryers. Processing takes place from about February to November when the factory ceases operation until the next season begins. During downtime, the plant machinery is cleaned, serviced, and upgraded ready for next year’s crop.

Drying the nuts in the shell is a critical step in the processing of macadamias. At harvest, the moisture content of the nuts is approximately 30% and the kernel fills the entire shell, but after about 3 weeks of drying this is reduced to around 1.5% and the kernel shrinks away from the shell. The shell can then be cracked without damaging the kernel and nut-in-shell storage life is prolonged. Nuts can be stored in their shell for up to two years.

Modern machines have been perfected to crack the nuts without damaging the kernel. There are two main types in use: the fixed plate with a cutting blade and combination rollers and base plate to compress the shell.

Many methods are employed for separating the kernel from a broken shell, including hand sorting, screens, flotation, air separators, and state-of-the-art electronic color sorters. These sorters differentiate between the dark brown color of the hell and the creamy color of the kernel and remove the shell fragments with a burst of compressed air. A final hand sorting inspection is carried out, to remove the low-quality kernel. Grading of styles and qualities is usually achieved using rotating screens.

Long-life storage is another positive attribute of macadamia nuts and this can further be enhanced by the use of nitrogen flushed, 11.34kg aluminum packets that ensure no oxidation and or rancidity.